Paper Considerations

Delicate & Highly Flammable: Paper is very thin, which makes it easy to cut, but also easy to burn. Always monitor your laser while it is on.

Inexpensive Options: Most paper tends to be cheap enough we can take the time to hone our laser settings with trial and error.

Shifting: Paper is very light and can shift in the workbed due to the exhaust fan or the air assist (the laser itself won’t shift paper). To prevent shifting, hold the paper down with small weights or tape.

Approach

General Approach

Paper is very delicate, so have lots of extra material for testing and refining your settings. Also, be fire aware and prepared. Hone your settings and dial in your vector current.

Cutting Paper

A CO2 laser affects paper by rapidly evaporating the material into visible smoke. With Air Assist, the smoke is transported away from the material, minimizing potential for burning or burnt edges. Ideally, our results will have clean edges with little discoloration.

Pro Tip! Some edge burn is unavoidable but can be reduced by lowering Current.

Engraving Paper

Paper can be engraved, but results vary. Thicker paper, such as construction paper or cardstock works best, as we are trying to achieve contrast through engraving depth.

Marking Paper

Marking paper should leave very little depth on the paper, and results in a contrasting shade that is light or dark, depending on the paper used.

Vector marking is great for creating stencils on top of projects. By adding a layer of masking tape you can use the vector marks to cut through just the surface of the tape creating a stencil on top of your design. Simply remove the tape where you want to paint This makes painting any project very quick and precise.

Paper Finishing Tips

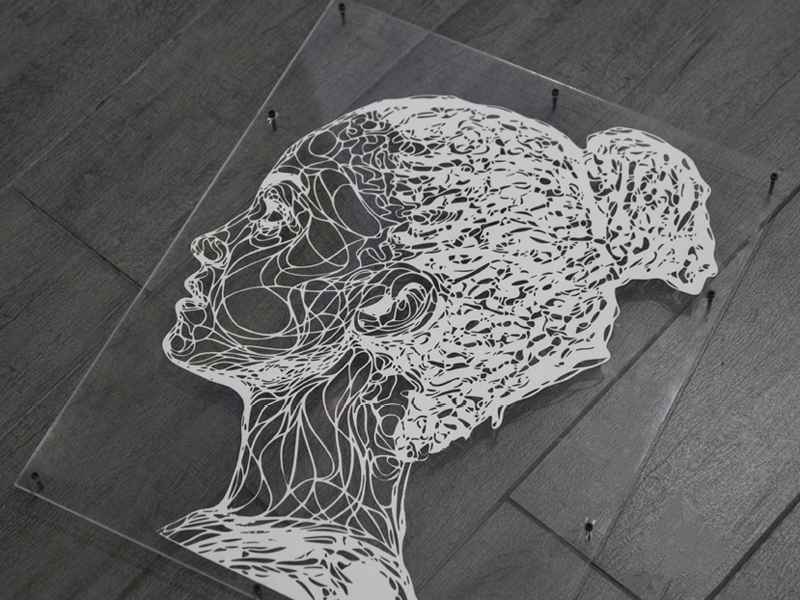

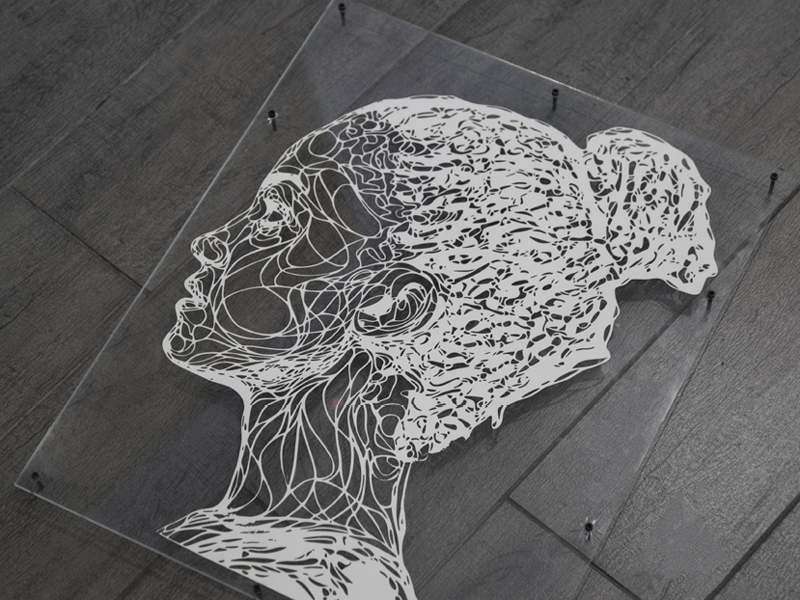

Preserving: Paper is very delicate after being lasered, which looks awesome but tears easily. Art pieces can be set in picture frames, or set between glass or acrylic.

Lighting: Add back-lighting to really make an impression.

Laser Settings

Your power, speed and other laser settings are going to vary depending on things such as the thickness and density of the paper you are cutting. Even the wattage of your laser and the local environment can affect settings. Because of this, instead of giving arbitrary settings, we recommend doing a materials test on a piece of scrap paper. You can download our Material Test and log book at our Laser 101 website.

If you enjoyed this blog, be sure explore our other laser related offerings such as ebooks, video tutorials and our weekly live shows, all free to Full Spectrum Laser owners and operators.