Laser cutters have a wide variety of functions and applications: from cutting to engraving to surface marking on a wide range of materials from paper to metal. That said, each type of laser has its own set of applications and no single laser can do everything with every material. That means a laser that can cut through a sheet of metal, may not be optimal for exact surface-making of medical equipment. And so, this blog is to help you get an overview of what different types of laser cutters excel at and what jobs require a different approach and laser system.

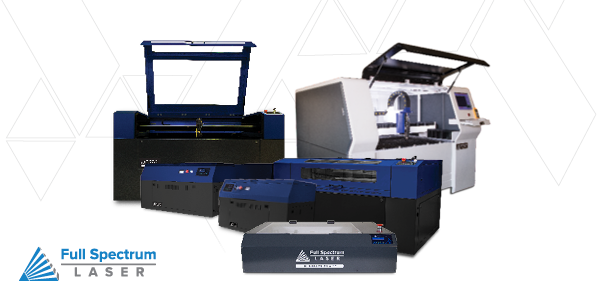

Affordable hobby lasers come with low power laser tubes (typically 40w) that are perfect for hobby scale cutting and engraving on many common materials. Quarter inch wood and acrylic work great with Muse, for example. As does paper, cardboard, most fabrics; even rubber, stone and glass have applications that work well with hobby lasers. If your projects center on these materials and you have low output requirements for small scale production, these lasers offer great value for your investment. What they can’t do is handle industrial production output, create large scale projects or affect metal in any way. They are also limited on the thickness of wood and acrylic it can cut (typically, a quarter inch).

Pro-Series CO2 laser systems increase the size, power and durability of what a hobby laser can do. Pro-Series works with the same set of materials as a hobby laser, but with laser tube power increases (up to 150w), can cut up to a half inch of wood or acrylic. Pro-Series machines can also provide a much larger working space for bigger projects. While the smallest Pro-Series is 20x12 (like a hobby) it can go all the way up to a 48” x 36” workbed. If you intend to create a heavy project output, if you want vastly increased laser power, and if you need a big workspace, Pro-Series is where you want to focus your research. And just like Muse, Pro-Series is not made to cut or engrave metal, but excels at cutting and engraving many other materials.

The Dual Head Laser system is most closely associated with a Pro-Series machine. With this system, a second 90w CO2 laser tube is added to create a two-front cutting system, allowing for instant replication of the design. The Dual Head is capable of anything other Pro CO2 lasers can do (with the same 90w laser tube). If your main requirement is to replicate the same non-metal product as fast as possible, then consider the Dual Head.

If cutting a wide diversity of material, including metal, is your goal, then the Flatbed CO2 is perfect. With a 150w laser tube, not only will it cut one inch acrylic and wood, it will also cut through 1.2mm carbon/stainless steel (steel only, see fiber lasers for cutting other metals). What this system doesn’t do is engraving or marking. If you want to engrave metal, you will need to look at FC/FD fiber laser systems.

The FC/FD fiber lasers are built to create fine engravings and surface marking on all sorts of metals and certain plastics. These are small fiber systems that work great on a wide set of applications including engraving firearms to exact ATF requirements, surface marking medical tools and other fine markings such as serial numbers on metal plates. Markings can be deep or leave the surface smooth and with zero roughness. Do not consider the FC/FD fiber systems if you want to cut material or mainly use wood or other non-metal, non-plastic materials.

The compact fiber laser boasts a 500w fiber laser that can quickly cut through a wide range of metals including carbon steel (up to 6mm), stainless steel (up to 3mm), galvanized plate (up to 3mm), aluminum plate (up to 3mm) and copper plate (up to 2mm). Like the flatbed CO2, is does not engrave any material. That said, the compact fiber laser is the go to machine if you want the fast metal cutting laser.

Of course there are many other considerations when researching the perfect laser system for your needs. Size, costs and other factors will surely play in your final decision, but this blog should help you focus in on what certain types of lasers can and cannot do. If you have any questions, please contact our sales team at sales@fslaser.com, and they will be glad to help point you toward the right machine.

.jpg?width=5472&name=Dual%20Head%20open%20front%20(print).jpg)

.jpg?width=2400&name=flatbed-3(large).jpg)

.jpeg?width=2400&name=Compact%20Fiber%20in%20use%20%231(digital).jpeg)