Create by Vector Cutting

Cutting requires an image that contains vector data. As opposed to images that use pixels, vectors are designed as paths that the laser can follow to produce your design. In this lesson, we will learn about: Selective Importing, Vector Properties, Vector Cutting, and Basic Assembly.

Safety First

Before powering on your laser, ensure that your workspace is free of fire, electrical and other safety hazards. Always be aware of all safety precautions when cutting materials with a laser.

Verify that your laser is connected to a computer by using the included ethernet cable.

For any additional setup or troubleshooting, reference your user manual for details

Launch Software

When the boot cycle completes, locate the unique IP address for your machine. For Muse, the wired IP will be listed in the bottom right corner of the touchscreen. To access the wireless IP, go to Settings>Network. For all other machines, use the IP address that appears in the main screen after the boot cycle.

Type this unique number into any web browser. We recommend Google Chrome for best results.

Step 1

Import

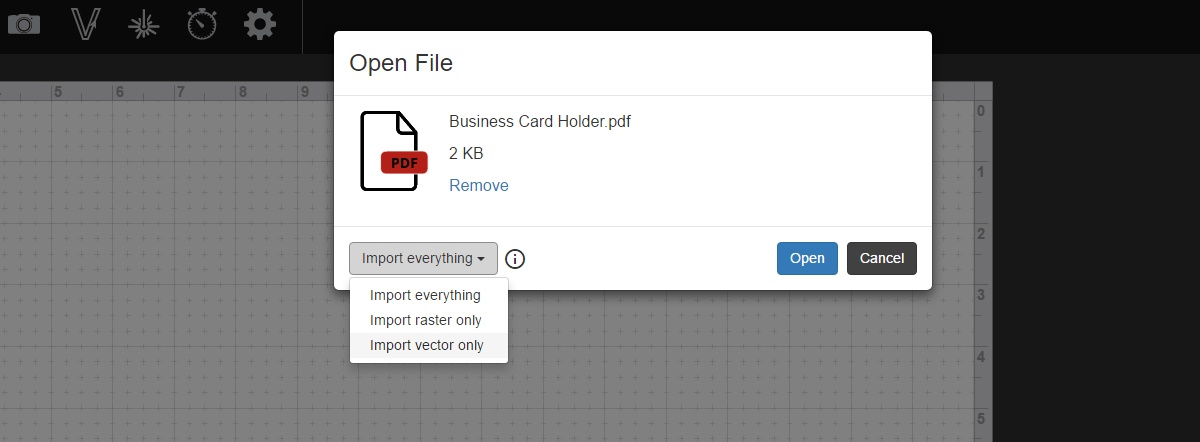

To begin, download the .PDF file below and import the design like we did in lesson 1. This can be done by selecting the import icon, or by dragging and dropping your file into the workspace. PDF files contain both raster and vector data. Since we will only be using vector data for this project, select "Import Vector Only" in the pop up menu that appears.

Step 2

Settings

Click on the image to select your design and open the settings menu on the right hand side of the screen. This design was automatically identified as a vector, and will display the vector properties menu.

Similar to raster engraving, speed will determine how quickly the laser head moves, while power will determine how much power the laser tube delivers.

We used (speed 30%, power 100%, current 100%) *Results will vary

Vector current is a control unique to vector files. Vector current controls the pulse of the laser. 100% will create constant power for smooth cutting, while lower percentages will add increasingly more off time between pulses. We will be using 100 current in this project for cutting, but if you choose to modify or experiment, this variable may be used to reduce the scorch marks on vector cuts, do fine vector marks, or to further lower the power for delicate materials.

As always, settings will vary with your tube wattage and type of material. It's best to test on an inconspicuous part of your material before creating your final piece.

Step 3

Run

Focus

Insert your material into the bed and use your focus tool to focus to the top of the material.

Positioning

If relaitive positioning is not already set, select the "settings" icon and select relaitive positioning. Position your laser to the top left corner of the material.

Jog

Jog the perimiter to test if your file will be within bounds. Make adjustments if necessary

Close the lid and press play.

Step 4

Assembly

When the file completes, there should be a total of 4 cut pieces. Attach the left side piece to the back piece using the corresponding tabs.

Next, attach the center beam to the left panel using the exposed tab.

Lastly, balance the assembly to expose the open side and attach the remaining side panel.

If perfered, you can add glue to each tab to secure the connection.

What We Learned

- How are vectors different than images?

- Vectors are paths while images are composed of pixels.

- What kind of data does a .PDF contain?

- Both raster and vector data.

- How do speed and power properties relate to speed and power in raster projects?

- Speed always controls how fast the laser head moves, while power always controls the power output of the laser.

- What does the vector current slider control?

- Vector current controls the pulsing of the laser.

- How does a vector job run as opposed to a raster job.

- A raster job runs like an "inkjet printer" marking what it sees. A vector follows the path of the design.

Materials:

⅛” Wood or Acrylic

Wood Glue or Super Glue

(Optional) Stain or paint

Things to think about:

- How are vectors different than images?

- What kind of data does a .PDF contain?

- How do speed and power properties relate to speed and power in raster projects?

- What does the vector current slider control?

- How does a run a vector job as opposed to a raster job.

Download

Design Files

|

(RE2)

|

|

|

(RE1)

.SVG |

|