So you have decided a laser cutter would be the perfect tool to take your crafting, business, or personal projects to the next level. Now all you have to do is decide which machine is best for your unique needs. Before purchasing your first laser cutter, answer these 5 simple questions:

1. What Will I Use It For?

1. What Will I Use It For?

Your first question should always be, “What will I use it for?” Generally, people fall into two categories: Hobbyists and Professionals. Hobbyists are artists and crafters looking for small scale production. Perhaps they want to start an Etsy shop or participate at maker-faires. Or they may just want to make unique gifts for their friends and family. If this is you, a hobby machine fits your goals. Hobby machines are typically compact, portable and affordable for individuals to purchase. On the other hand, if you are running a full time business in a heavy use workshop, hobby machines aren’t going to have the power, speed and power you require. If your goals are production based, professional laser cutters can handle a full day's workload on an industrial scale.

2. How Much Power Do I Need?

Laser tubes come in different types to cut many different materials. Unless you have an unlimited budget, you are going to want to decide on a particular machine for your particular needs. For example, if you are only intending to cut quarter inch wood, you won’t need to purchase a much more expensive metal cutter. On the other hand, if you do want to cut metal, a machine with a 40W CO2 laser tube isn’t going to “cut” it. Once you know what type of materials you want to cut, you can focus in on the laser wattage you will need.

3. How Big is the Material I Want to Cut?

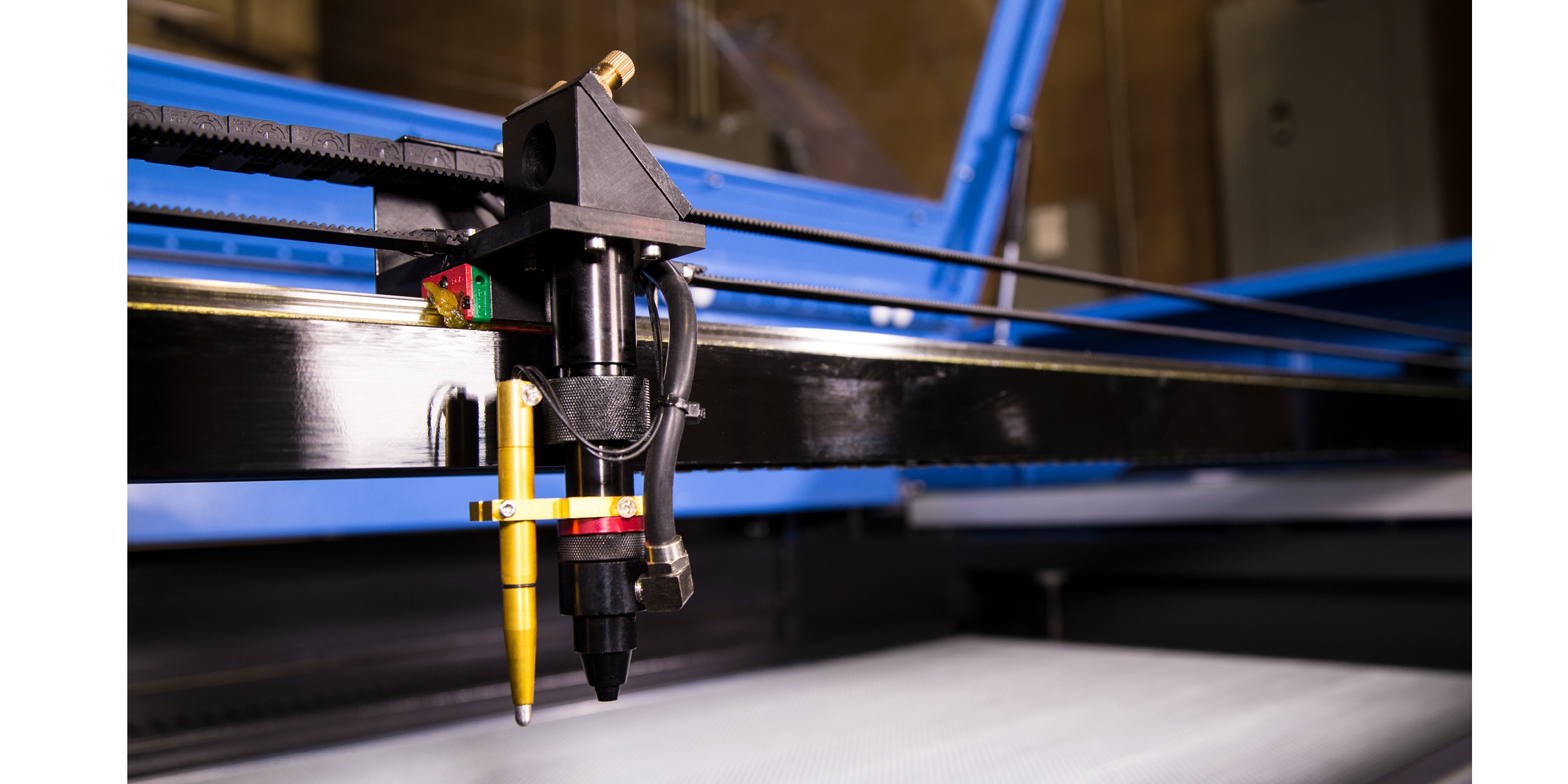

Laser cutters can also be defined by how large a workspace they have. Smaller hobby lasers, have a 20 inch by 12 inch work space, meaning you are limited to working with smaller materials. If you have 36 inch wide plywood you want to cut, you will need a minimum of 36 inches wide of workspace. The size of the machine will also be limited by your workspace or warehouse. Keep in mind, any machine with a bigger workspace than 20” x 12” is going to be large and heavy requiring a forklift and a large space.

4. What Is My Budget?

Budget is something you don’t often have much control over, so making sure you get the most for your dollar is crucial. You don’t want to overspend on a machine that cuts metal, if you never intend to cut metal. On the other hand, if you material is 30 inches wide, a 20 inch work bed isn’t going to be enough. When you research the laser market you will find a wide range of machines and prices. Look to fulfill your minimum needs first, and then worry about price. Often you will find a range of prices for the size and type of laser cutter you want. And remember, you can always ask about financing, if you need to.

You have many options for laser cutters, but there is one machine out there that is perfect for your needs. Take your time and research all your choices and make sure you find a match to your unique laser cutting needs.