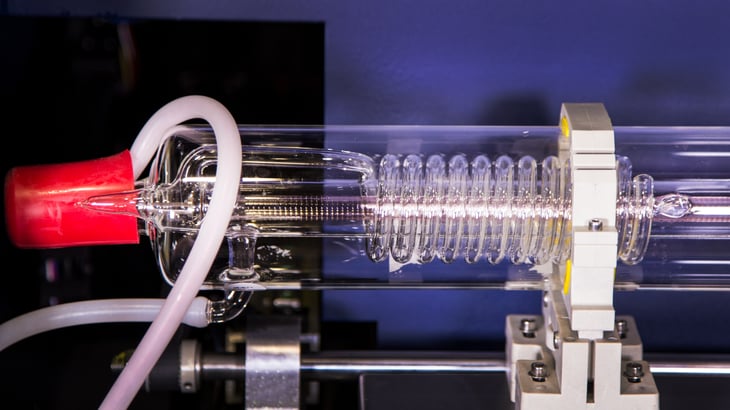

Lasers can be hot. That is pretty obvious and necessary to the function of a laser cutter. Ironically, the real key to keeping your CO2 laser tube running to maximum longevity is keeping the laser tube as cool as possible. Typically, this is done by running water through the laser tube when it fires. From that simple concept, laser operators have a few options for optimal laser tube cooling systems.

Water Pump Systems

At minimum, a CO2 laser tube will require room temperature water to run through the laser tube when the laser is firing. Water pumps certainly achieve this bar with a simple flow system. Typical issues with this system include the need to replace the water often (it is typically not a closed system) and keeping the water at minimum, room temperature. Temperature issues can especially be a problem in hot regions where outside temperatures rise above 90 degrees. If your water being circulated through the laser tube is warmer than room temperature, you may be reducing the longevity of your laser tube.

Chillers

Chillers are closed water cooling systems that offer many benefits over water pump systems. Typically, chillers monitor the water temperature and warn the operator if the water becomes too warm. Many chillers, as the name implies, can cool the water to temperatures below room temperature, which is ideal. Finally, chillers use less water and don’t need to replace the water as often, due to the entire cooling system being enclosed in a single, water-tight unit.

Radiator Chillers

Radiator chillers offer a temperature alarm (if the water becomes too warm) and a circulation alarm (if the water stops flowing through the laser tube). They don’t cool the water but do give operators a constant, current temperature indicator. These units are great upgrades for hobby laser cutters, as they keep the water temperature monitored automatically and are more compact and neat than a water pump and bucket system.

Refrigerated Chillers

Refrigerated chillers take the extra step to keep the water below room temperature using a thermostat and constant temperature control. They offer all the whistles and bells (indicator alarms, closed system) of radiator chillers with the added benefit of cooler water. In all cases, cooler water means longer life for your laser tube.

Industrial Chillers

Very large laser cutters are going to require industrial chillers. Water pump systems and small chillers are not going to be able to handle 150w + laser tubes. As these tubes can be expensive, it is economically in user’s best interest to make their life as long as possible with an industrial cooling system.

CO2 laser engravers require water to keep laser tubes cool, and the cooler the tube, the longer it will last. A good investment in a chiller system can pay for itself over the course of many tube replacements as well as make your working area cleaner and more efficient.