As a follow up to our popular Designing for Laser Cutting Ebook, we are proud to present our latest offering to our fans: Return On Investment: Starting a Business with Your Laser. In this ebook, we discuss the process of choosing and getting the best results from your laser cutter from a business perspective. For this series of blogs, we will highlight a business utilizing laser cutters and engravers to demonstrate how one might find their own return on investment. In this installment we look at Tom's Terrific Signs.

Tom has had his own sign making business for ten years. He specializes in custom designs for small shop owners. Tom’s business uses many tools to make their signs, including band-saws, routers and stencils (which are often only used once). The process for each sign is long and laborious, requiring great skill and meticulousness from his craftsmen. Tom also finds he must have multiple tools on hand for different materials his customers may want. Tom is looking for a way to reduce costly errors in manufacturing and modernize his business to be faster and more efficient.

Tom’s Professional CO2 Laser Cutter

Tom realizes his tools are getting old and will need to be replaced. Then Tom discovers an alternative to making his signs using a professional-grade CO2 laser cutter.

Repeatable Precision: The nature of Tom’s business means that if a crafter makes a mistake during production, Tom must eat the profits for that sign. Although his staff is skilled and careful, making signs individually, by hand, always has risks. With a laser cutter, Tom knows every sign will be cut and engraved to the exact specifications he has determined. This means less wasted time and material.

Improved Estimates: Tom used to struggle estimating time and labor costs for odd jobs, such as signs requiring intricate designs. With his laser cutter, that process is all automated. The software informs him how long a job will take based on the intricacy of the design, the power settings and the material.

Industrial Production: Tom relies heavily on human labor, which is costly and slow. Tom discovers his professional laser cutter can continuously operate at a high production rate with only one employee to monitor and feed the machine. With an automated process, this single employee will only require training and certification on one tool.

Versatility: Tom has multiple tools for every material he uses for his signs. When he expanded his signs from exclusively classic wood to other material options, such as acrylic, he found his business boomed, but he was forced to invest in more tools. Then Tom found that his laser cutter works just as well on wood as acrylic (and many other organic materials). He uses the same machine and process no matter what material the sign is made of.

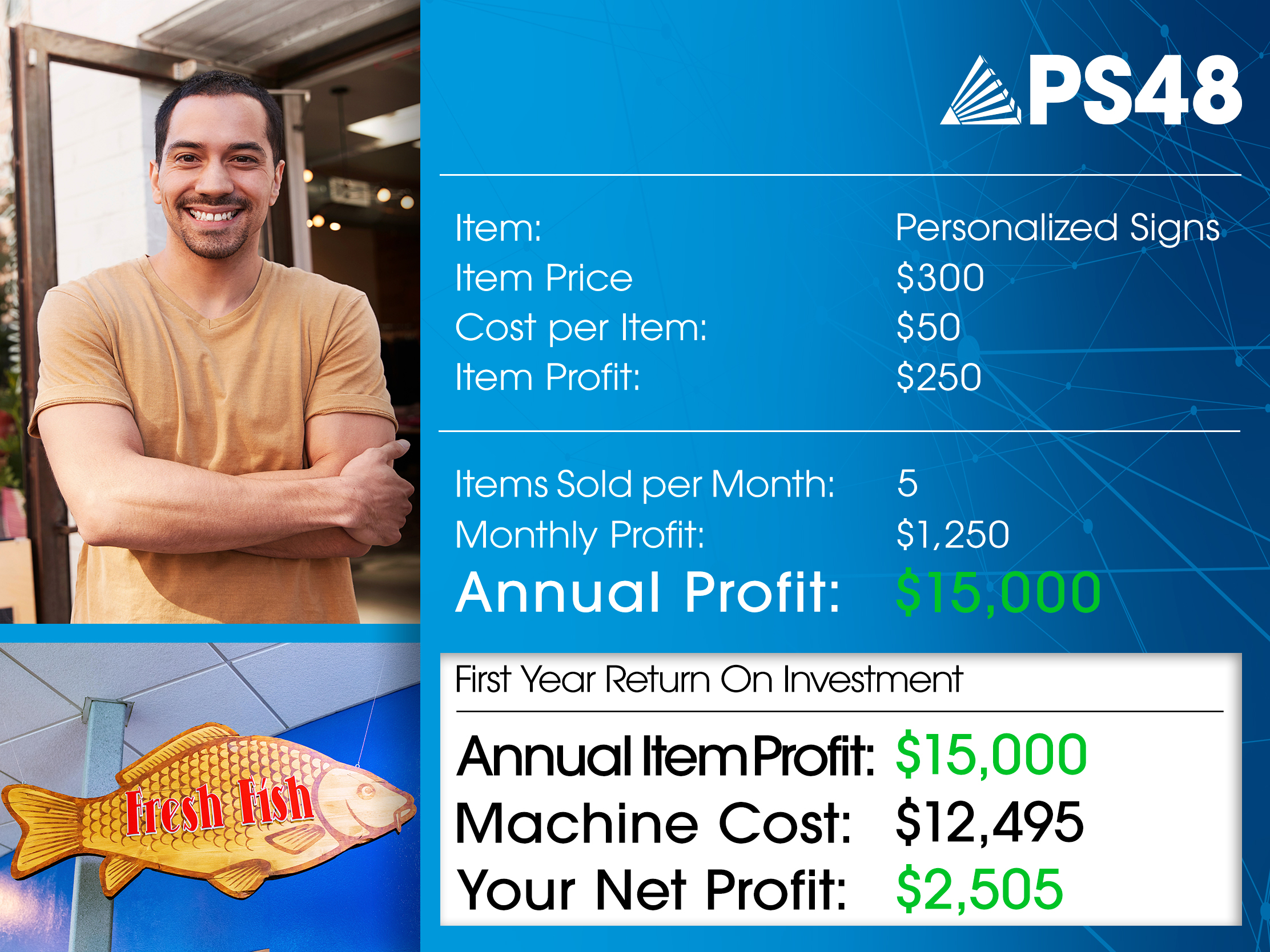

Profit Analysis: In Tom’s business, time is money. Each sign is a custom order and requires a design stage as well as a production stage. Tom has found it easy to request logo images from the companies he does business with and integrate them seamlessly into the laser software. The automated process then cuts and engraves the sign to exact accuracy. Tom increased his profit per sign by reducing his labor cost to one machine operator, by saving time in designing the signs using design software and by increasing his output while reducing human error.

See more laser business ROI profiles by downloading the complete ebook, Return On Investment: Starting a Business with Your Laser. Exclusively from Full Spectrum Laser.