Gravestones & Memorials: Very popular application for personalized engravings to honored family members, heroes and beloved pets. Typically applied to granite, marble or sandstone (flagstone).

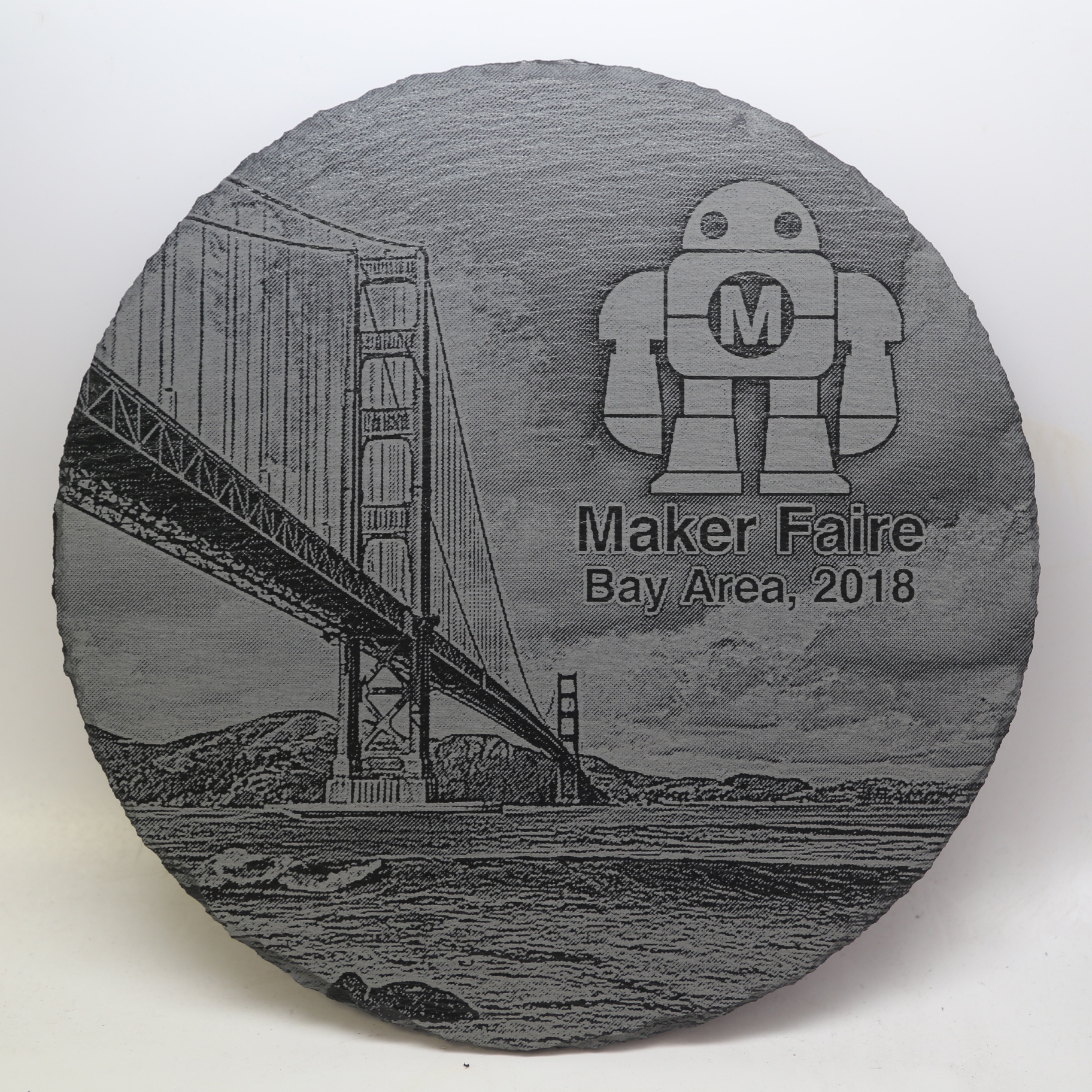

Art: Engrave dark stone is perfect for spectacular details in photo engraving. Marble and dark granite deplays great contrast and looks incredible on a wall in a living room or office.

Custom Flooring: Engrave logos, quotes or other branding concepts that you want to display prominently on floor tiling or marble surfaces. Works best with tiled flooring to create patterns or draw the eyes to a message.

Desk Accessories: Engraved marble name plaques and river rock paperweights marked with company logos are just two possibilities.

Signage: Stone signage weathers extremely well and gives a rustic feel

Outdoor Decor: Engraved rocks are great for decorating outdoor gardens and patios.

Personalized Hearthstones & Cornerstones: Add personal touches to fireplaces or commemorate the family home.

Novelty Gifts: Engraved river rocks make wonderful gifts for souvenir shops.

Honoring Fundraisers: Engrave brick plaques are popular ways to entice and thanks sponsors and promote fellowship.

Stone Considerations

Hardness: Stone is too hard for cutting with a laser and deep engravings have mixed results.

Surface Variance: Smooth or polished stone works best for engraving. Stone that is rough has less detail and can disrupt the image.

Shape: Stone can be found in all sorts of shapes and sizes. A flat, even surface works best.

Contrast: Like glass, the laser creates microfractures on the surface of the stone, creating a white engraving. This contrasts very good contrast on dark stone such as black marble.

Veins and Grain: Many stones have “veins”, or heavy graining, which create irregularities in engraving and marking. Choose stone with a low concentration of veins or position your marking away from veins.

Approach

General Approach

Much like engraving glass, the laser does not actually incinerate the stone, but rather leaves small microfractures on the surface, which create contrast and detail in marking and engraving. Shallow engravings work best and create the most contrast and detail on stone. Deep engravings have poor results on most stone and can be difficult to achieve

Cutting Stone

Stone is too dense for cutting. You will only waste precious laser power trying.

Engraving Stone

Follow basic rastering technique. Convert a high quality photo to a grayscale bitmap format and set resolution. Adjust power and speed to the density of the stone for a clean surface raster. For dark stone, you will want to “negative image” your photo in software.

Stone Finishing Tips

Stone doesn’t need much in terms of preserving, but you can add color to your engravings. The porous nature of most stone makes lacquer based paint absorb the color well. Avoid using acrylic based paints as these are not absorbed by stone and tend to make a mess.

Your power, speed and other laser settings are going to vary depending on what kind of stone your are marking. Even the wattage of your laser and the local environment can affect settings. Because of this, instead of giving arbitrary settings, we recommend doing a materials test. You can download our Material Test and log book at our Laser 101 website.

If you enjoyed this blog, be sure explore our other laser related offerings such as ebooks, video tutorials and our weekly live shows, all free to Full Spectrum Laser owners and operators.