One of the most common questions we are asked is, “What should my laser settings be?”. Our answer is usually to tell the operator to begin a materials test log and slowly hone in on the setting that works best for them. While we could give setting suggestions for various materials, we have found many factors can affect proper settings outside of the laser itself. The truth is, two people could be cutting the same type and size of material and require different settings. Here are some things to consider when looking for standardized laser settings:

The Environment

Are you using your laser in cold weather or hot? Are you at sea level or in high altitude? Our facilities are in sunny Las Vegas, Nevada; and when we say sunny, we mean temperatures that can soar over 110 degrees in the summer! We’ve been cutting material in these conditions for years, but we know our settings don’t reflect an average environment. Be aware that extremes in temperature, air pressure and humidity may require you to adjust your settings.

Machine Maintenance

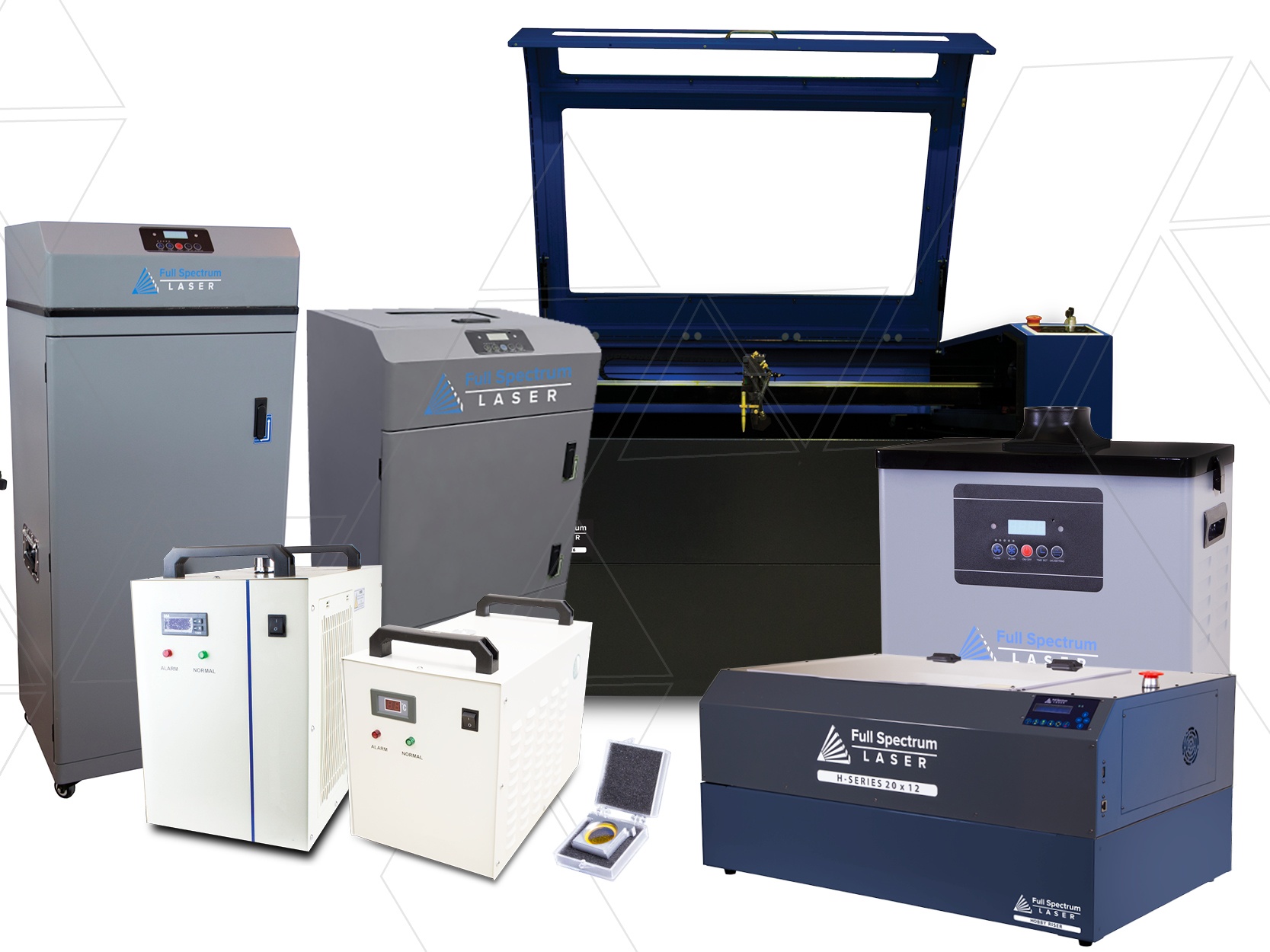

Varying states of cleanliness can also affect settings. Keeping your laser cutter clean is required for optimal performance. Mirrors must be cleaned and the laser bed should be free of debris from prior projects. Also, keeping the laser tube cool with a chiller system can increase the life of your laser tube. Your user manual will have detailed maintenance instructions that will keep your machine’s results amazing and consistent.

Material Quality

Material manufacturers can vary in quality and consistency In general, the higher quality material, the better the results will be. For wood projects, we use Rowmark’s Hardwood Collection because it is made for laser cutting and laser engraving, and gives much more consistent results than normal wood Edge joint and kerf bending projects, in particular, benefit from this product because natural wood can have uneven thickness and make assembly difficult. For acrylics, we recommend Rowmark’s laser and rotary engravable plastics These are also high quality, high consistency materials made specifically for laser engraving. That said, two pieces of wood from the same lumber yard (or even the same tree) might be affected by a laser slightly differently, requiring their own custom power settings.

Material Log

A material log is used to record power/speed/current settings for different materials Keeping a detailed material log is highly recommended We offer a free material log and a material test template at the Full Spectrum Laser website. Watch Nick and Walker show you how to use the Material Test File to find and dial in settings with your laser system.

For more helpful advice from your friendly neighborhood Laser Experts, check out Laser 101, featuring free project files and design tips!